Bicol´s Pride: The Pili-Nuts

|

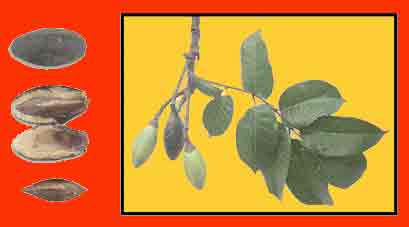

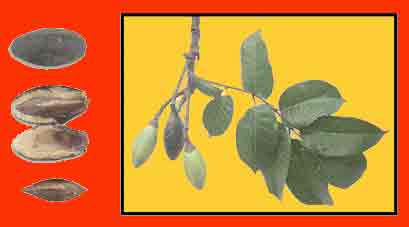

If you travel to Bicol, there is mostly an offer of roasted and sugared pili-nuts by street vendors or in special shops. There are more than fifteen merchants for instance in and around Legaspi City. Perhaps you are first a little bit skeptical. Should you really spend round about 300 Pesos for 250 grams of brownish pili nuts in a relatively bare plastic-box? A taste will quickly change the initial restraint into great delight. "Yummy, yummy.... masarap" , may be you comment and before you know were you are the box is empty. The pili nut is little known in Europe. Reason enough, to have a closer look at this fruit, which is in a strong biological sense no nut but a stone-fruit. The pili tree is endemic in the Philippines and here especially in the province Bicol, where round about 70 % of the trees are standing. Only in the Philippines, the fruit has a market. But in the meantime there are also trials of commercial farming in Hawaii. Pili trees are located in the free nature there are for example very old stocks of trees near Mount Bulusan -, but now more and more farmers are planting pili trees with help of the local government. In 1998, the province of Bicol counted an farm area of nearly 1.600 hectares planted with 57.000 productive trees and a harvest of approximately 9.000 tons. These figures may have doubled meanwhile, because the government distributed 330.000 seedlings to farmers, households and schools. The symmetrically shaped, densely foliated, evergreen tree can reach a height of 20 - 30 meters. It is storm-resistant and starts fruiting 5-6 years after seed germination. Female trees are much more productive than male trees. At present there are trials to growing time by grafting and cloning high prolific plants. A fully developed tree produces approximately 100 - 150 kg raw nuts per season ( May to September) , when it is twelve to fifteen years old. The tree is ideal as a shadow giving street tree, lawn or border tree. The trunks can be used for building constructions, furniture, handicraft and burning material. The resin is used for pharmaceutical products and colors. Cooked young-shoots can be processed to salads. Let's come to the fruit now. After the fertilization of the bloom, the fruit needs twelve months for ripening. The oval raw fruit is 4-7 cm long, has a diameter of 2 - 4 cm and weighs 16 - 45 grams. The pulp is coated by a thin, soft and shiny skin (Exokarp), that colors itself with increasing maturity from light green to black. If the greenish pulp gets cooked its taste reminds of sweet potatoes - and spiced with salt, pepper or fish-sauce it can be processed to meals. It is possible to extract oil from the pulp (12%) and the oil can be used for the production of lamp-oil or soaps or can be fed to pigs and cows. The next component of the fruit is the long stretched, triangular, hard nutshell (Endocarp) with a yellow to dirty brown color. The peels are used as burns or processed to decoration-material or charcoal. Their smoke can also expel mosquitoes. The real nut (Kernel) is coated by brown, paper-like skin and weighs only 0,7 - 5,2 grams. That corresponds only 4 - 17% (!) of the raw nut. The amount of rejects is remarkable - also in the comparison to other species of nuts. After the harvest, the watered raw nuts are freed from the pulp and get dried for two to three days. After this procedure the stone-fruit can be stored up to one year without any loss in quality - for example in expectation of better sale-prices. In order to get the real nut, the stone-fruit is dipped into hot water and the nut is removed from the peel with help of a Bolo (knife). Later as we will see - the nut is object of further processing-steps. The raw nut has the taste of toasted pumpkin-kernels and has laxative effects. If it gets roasted it surprises by a mild taste, that is superior to that of almonds. 100 grams of the nut meat have round about 600 kilocalories. The nut is rich of proteins, magnesium, phosphates and potash. The fat content of 70 percent lies higher compared with the more popular Cashew nut. This may be an obstacle with regard to the marketing of the nuts. Saturated fatty acids are in the majority, but today it is possible to increase the level of unsaturated fatty acids by a procedure called fractional crystallization.

There are also other recipes for meals. Pili-pudding is produced from a mixture of pressed sweet potatoes, pili-kernels, condensed milk, butter, sugar and eggs. The mixture is spiced with vanilla and gets baked brown in slightly greased cookie pans. Pili -Turro needs first the cooking of a thick syrup from sugar and water. Later pili nuts, vanilla and salt are added. The cooled mass gets flatten by using a rolling pin. Then, it is cut in shapes and wrapped in wax papers. Marzipan products can be made from pili nuts and the nuts are also ingredients for ice creams, chocolates and cakes (for example in the famous Chinese moon-cake).

more favorable credit-possibilities for the farmers optimized pools of seedlings more advanced processing-technologies and a broad marketing-concept, that has to include far more than the annual pilinut-festival in Sorsogon (20th of June) Because of high assessed export-potentials, the government has elected the pili nut as flagship-product of the impoverished province of Bicol and has promised supports to farmers, processors and dealers with regard to the commercial exploitation. Let's wait for the agrarian-statistics of the next years if the hard nut of this challenge can be cracked. © Wolfgang Bethge, 2003 |